IoT

PabrikPintar

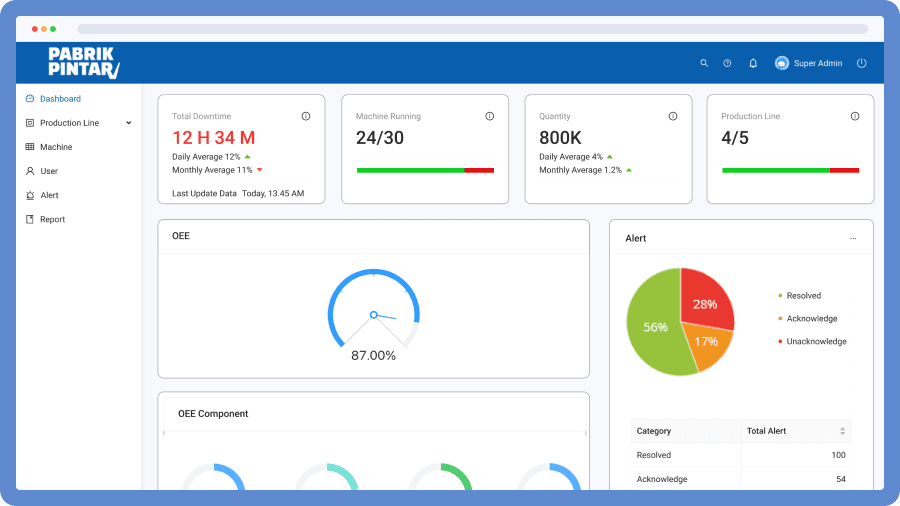

Pabrik Pintar is an innovative smart factory solution designed to enhance productivity, optimize production costs, and ensure efficient operations through digitalization. By leveraging IoT technology, Pabrik Pintar enables real-time monitoring and data analysis, allowing manufacturers to make informed decisions and improve overall efficiency.

Real-Time Data Monitoring

Utilize IoT gateways and sensor nodes to collect and analyze data from various sources, including sensors, PLCs, and OPC servers, ensuring continuous oversight of factory operations.

Operational Efficiency

Increase factory productivity by monitoring Overall Equipment Effectiveness (OEE) and critical process parameters, leading to improved production targets and reduced costs.

Predictive Maintenance

Employ advanced analytics to forecast potential issues, enabling proactive maintenance and reducing downtime.

Comprehensive Environmental Management

Monitor electricity consumption and environmental conditions across the factory to support sustainability initiatives.

Why Business Choose Tritronik PabrikPintar

Enhanced Productivity

Achieve significant improvements in machine efficiency and reduce quality loss by up to 90%.

Cost Reduction

Optimize energy usage and automate routine maintenance tasks to lower operational costs.

Data-Driven Insights

Access historical data and real-time analytics to inform decision-making and improve production processes.

Scalability

Easily integrate with existing systems and expand capabilities as needed.

Smart Alerts & Notifications

Receive real-time alerts for equipment failures, security breaches, or environmental changes.

Centralized Control

Manage multiple production lines from a single interface, enhancing oversight and coordination.